Our production process consists of multiple phases and each one is carefully controlled to guarantee complete traceability of all handled materials. To comply with high quality standards, we consider purity as a primary aspect.

Plastic processing

Sorting of raw materials

Upon arrival at our production plant, the waste is subjected to a preliminary inspection. The sorting process is made with a supplier, by polymer and chromatic gradation.

Agglomeration or Grinding

Flexible waste undergoes an agglomeration process, allowing a volumetric reduction. The output is a moisture-free agglomerated, pivotal for the following compounding phase.

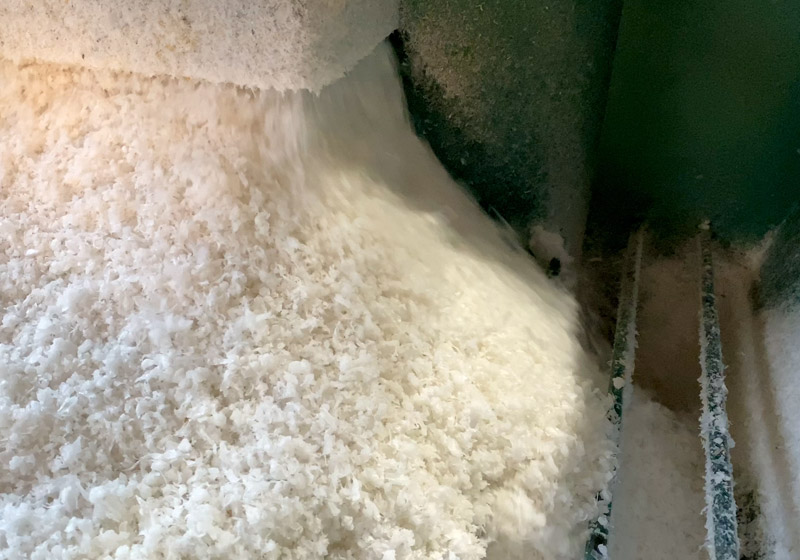

Rigid waste is ground by means of a mill, which reduces it to a homogeneous size.

Extrusion

An optimal blend of agglomerated and regrinded is the input of the extrusion process. Polymer melts inside the extruder and is filtered from impurities. Cutting, cooling and spinning are the final steps of the process. The output is a granule with homogeneous technical characteristics and a lenticular shape.

Sorting of raw materials

Sorting of raw materials

Agglomeration of grinding

Agglomeration of grinding

Agglomeration of grinding

Extrusion

Extrusion

Extrusion